At IFSYS, customer relationships are based on advice, engineering and service. With this attitude we advise, develop, simulate and design. We search and find an expedient solution for (almost) everything and we stand ready to provide our customers with advice and support at all times. Fairness and trust are the keys to successful and long-term cooperation.

Planning and controlling. Throughout the entire project, our project management division takes care of the seamless realization of projects and acts as a link between the customer, sales, product development, production planning and quality assurance.

Planning and controlling from the first solution approach right through to assembly and commissioning is competent, flexible and targeted. That means interface assurance, the customer order is defined as a complete process including resources and deadlines, and is supported right through to the completion phase.

With our stock of standard spare-parts, we support our customers individually and without excessive delays due to transport times and customs problems.

We pursue a holistic quality concept that encompasses management responsibility right through to the continuous improvement process. The resultant customer advantage lies in planning and product assurance, batch purity in production, high quality, product traceability, system partnership and innovative strength.

The customer requirements for feeding technology use in series of production or assembly include shorter production times, variant changes, new materials and coatings. High manufacturing competence, vertical integration and system understanding make IFSYS a competent partner for demanding projects - with individual and complete solutions, components and reproducible systems.

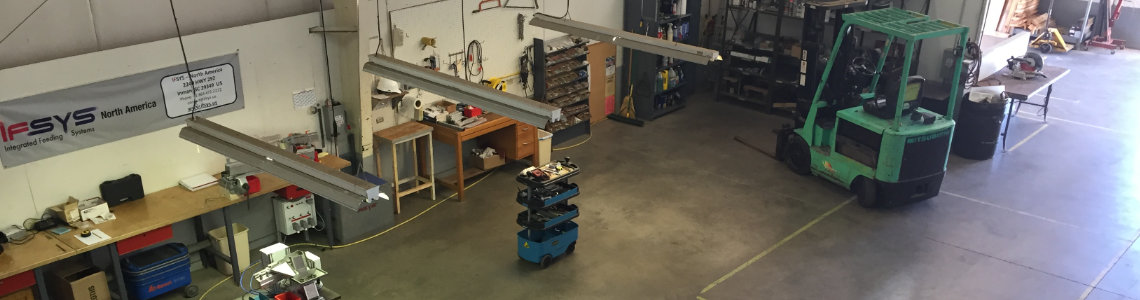

The equipment of machines are built up with internal know-how according to the state of the art. This results in advantages such as high flexibility, adaptability and individual innovative solutions. The production process and workflows is flexibly aligned, networked and increasingly digitized according to the principles of individual production and customer-specific mechanical engineering.

Following assembly and commissioning, we offer a comprehensive range of services for all equipment and devices: Service and maintenance work, qualification of customer personnel on site, overhauls, original spare parts, as well as conversion and repairs. Performed reliably and flexibly by service personnel who are highly familiar with the technology.