Flexible supply of parts with a vibration system

PICKNICK is a flexible parts supply with a vibration system based on a hard plastic tray or a conveyor belt. Our PICKNICK vibration system distributes, turns or rotates the products in the detection range of the vision system.

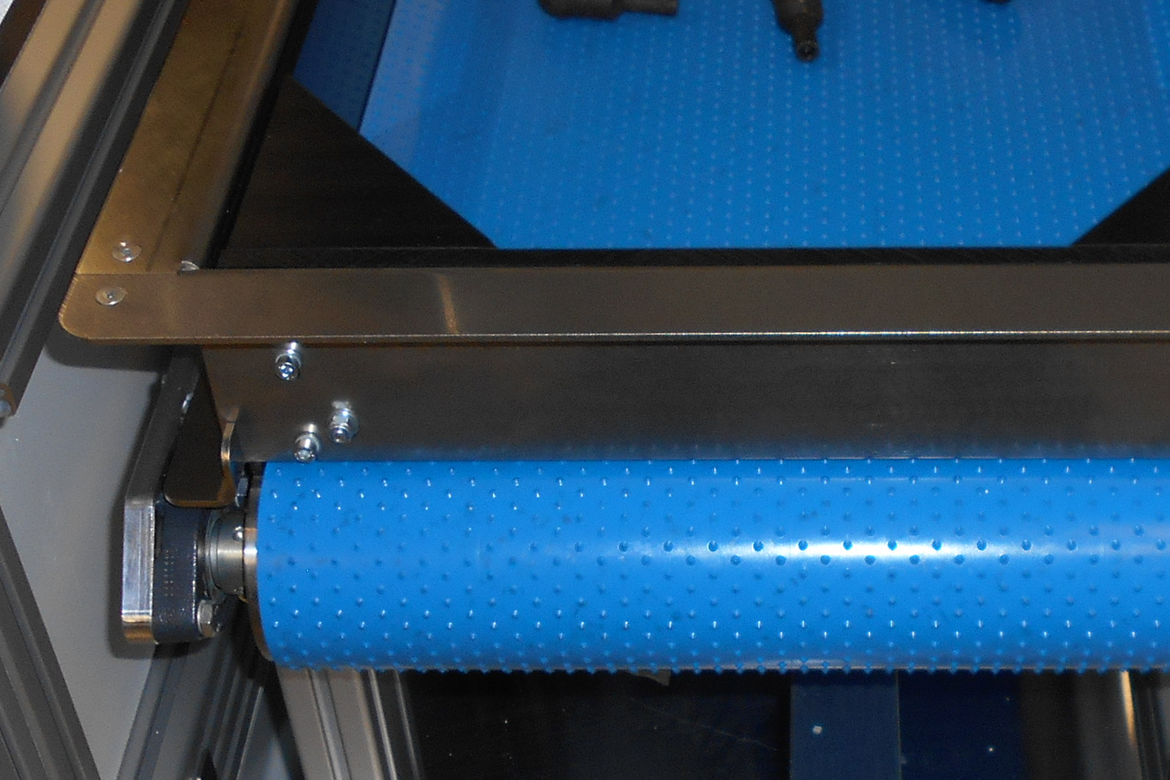

For PICKNICK with backlighting, the vibratory tray is the ideal solution. For PICKNICK with vibro belt: incident light with color camerasor monochrome is used.

It is possible to get our flexible feeding system, additional with stocking system, with camera system and with robots of all brands (also collaborative)-supplied by IFSYS. The electrical version can be supplied unmitted, installed on Profinet interface optionally offered with control system.

Our answer for tasks with variable feeding tasks: PICKNICK

From practice

various belt- and traydesigns

low wear of parts

purely electrical drive

suitable for almost all cobots and robots

universal for any sorting parts

changeover to other sorting parts possible only by software

flexible lobation

driven by simple, proven technology

flip-speed individually adjustable and changeable

different belt colors for better contrast

Camera with mono or 3D technology

dirt collection tray

Your complete solution for almost all parts

Flexible feeding solutions are a nice solution, especially for applications with frequently changing parts geometries. By cooperation of robot, feeding system and integrated image processing, many different parts can also be sorted, aligned and fed even in small batch sizes. By providing different sorted parts to the robot at the same time using several PICKNICK systems, feeding flexibility of the supply can be increased.

Delicate and small parts: If skill and precision are required during feeding, PICKNICK with Vibrotray is the ideal solution. The backlight enables small and filigree contours.

Heavy and large parts: PICKNICK with Vibrobelt is flexibly adaptable to different feed parts and can also separate and detect heavier asymmetrical parts.

Before placing an order for the construction of a machine, it is often useful to create a feasibility study. Especially if a process development is pending, preliminary tests are made or sample parts have to be manufactured.

The test workshop at IFSYS is specialized in feasibility studies, test reports or simple tests in advance. If desired, a prototype can be drawn and built.

If we have sample oarts or drawings, we can make specific statements for your production.

We look forward to your inquiry