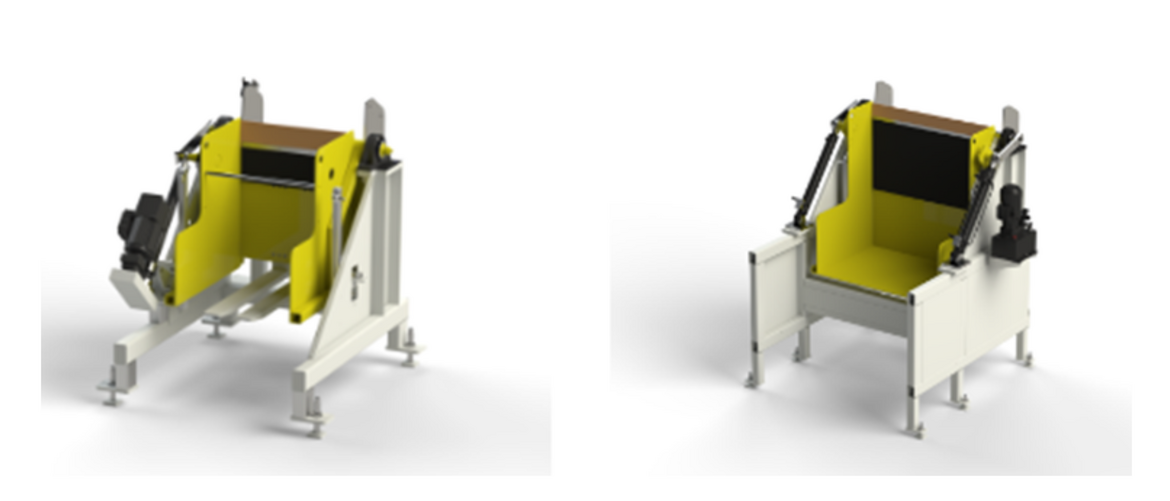

Tilting devices – customized ergonomics and efficiency

Our tilting devices are the ideal solution for automating manual processes in production, making the working environment more ergonomic and increasing efficiency. We design each tilting device individually according to customer requirements so that it fits perfectly with the specific containers and production processes. Thanks to our expertise, everything comes from a single source – from planning to commissioning.

Advantages for production

Our tilting devices offer a number of advantages that have a direct impact on production processes:

IFSYS solutions for tilting devices

We offer two types of tilting devices, which differ in terms of their drive type and load capacity:

Safety and adaptability

Safety is our top priority. Our tipping devices can be equipped with the following optional features::

For further information on our feeding systems or feeding modules, we kindly refer to the specific product descriptions. If you are interested, please get in touch with us.